SAKE BREWING PROCESS

the following steps are an example of fundamental flows in our sake brewing process.

-

STEP 1. SAKE RICE

Carefully selected rice from various regions arrives in the rice storehouse in Yoshino-Shuzo. -

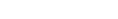

STEP 2. RICE POLISHING

We start with polishing the outer layers of hulled rice.

Our rice polishing machine starts running a month before the toji and kurabito arrive and keep running until early January. -

STEP 3. AFTER POLISHING

Sake rice after polishing goes through karashi (aging) to gradually retrieve moisture

by absorbing moisture in the air.

Nuka powder (rice bran) from polishing is categorized into four types by the grade of polishing: aka-nuka, chu-nuka, jo-nuka, and tokujo-nuka.

Aka-nuka and chu-nuka are utilized as chicken feed.

-

STEP 4. STEAMING

Sake rice then goes through washing and soaking (to absorb water).

Target water content from soaking varies depending on type and characteristics of sake rice and the type of sake to craft,therefore we need to manage the length of soaking time to be adequate for each rice.

After soaking, rice is steamed in a koshiki (steaming vat) placed a top of cauldron.

The maximum amount of rice to be placed in the koshiki is 1 ton. -

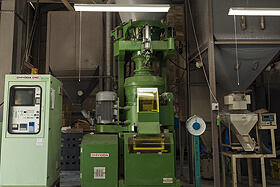

BEFORE DAWN

There is a gradual brightening of the sky to the east.

Up in the sky is shining the pale blue light from the moon.

Before dawn in the early winter, it gets so cold outside even in Katsuura that we see our breath. -

The brewery and its surroundings are filled with the aroma of steamed rice and foggy steam.

-

A blanket covering the koshiki expands after an hour of steaming. -

STEP 5. COOLING

The steamed rice is cooled down to a certain temperature by a rice cooling fan. -

We gently spread the steamed rice out by hand.

We target specific temperature of steamed rice by its usage such as koji, moromi, or shubo (moto).

-

The cooled rice is laid on the blanket and then transported to the koji-muro (koji making room). -

STEP 6. KOJI MAKING

Koji rice is made after 2 days in the kouji-muro. Then, the koji rice is mixed in a tsubodai (a starter tank) with water,kobo (yeast), steamed rice, and lactic acid into shubo (moto, or yeast starter). -

STEP 7. MOROMI PREPARATION

Moromi (the main mash) preparation process is a 3-staged process in one tank.

First stage is called soegake, in which shubo, water, koji-rice, and steamed rice are mixed together.

As we move up to stage 2 and 3, we increase the amount of steamed rice and water to add in the tank.

The moromi preparation for Futsu-shu (low-grade sake) is called Ojikomi (large preparation) wherethe moromi from the maximum of 1,850 kg of white rice undergoes approximately 20 days of fermentation (brewing) in a large tank and then pressed. -

STEP 8. PASTEURIZATION AND STORING

After pressed, new sake undergoes oribiki (removal of sedimentation), filtration, and hiire (pasteurization) before it is left to age slowly in the storage tank in the brewery before shipment.

before it is left to age slowly in the storage tank in the brewery before shipment.

Nama-zake (unpasteurized sake) is stored at a low temperature in the thermal tank, or it is stored in the refrigerator after bottled. -

STEP 9. BOTTLING

Sake is bottled after the bottles are washed.

Bottled sake undergoes our strict inspection using a light to see through.

Only those bottles of sake that passed the inspection get labeled and await the shipment. Back to top